RECOIL OFFGRID Gear Projectile Protectors – Part I: Armor Plates

In This Article

According to the Small Arms Survey, American civilians owned an estimated 393 million firearms in 2018 — that number has undoubtedly grown considerably in post-COVID years. The vast majority of those firearms will never be used maliciously against another human being, but as with any tool, some will inevitably be misused to harm the innocent. If you consider yourself a prepared individual, are concerned with protecting your family from violence, have an active shooter plan, or are just a firearms enthusiast — and I imagine you’re one or all these things if you’re reading this magazine — you should seriously consider owning a set of body armor, or “plates” as they’re often referred to.

Above: Ideally, your front armor plate should be positioned just under the notch at the top of your sternum and should be at least wide enough to cover both nipples.

With advances in ballistic technology, rumblings about legislation banning civilian body armor ownership, and recent violent crimes around the country, responsible and discerning citizens are considering their need for body armor more than ever. As with most big purchases and competitive industries though, there’s a litany of misinformation, snake-oil, and ratings that frankly confuse the consumer. Today, I’d like to cut through the marketing jargon and talk about real-world performance and applications of body armor. I’ll also outline the different materials that plates are made from and their trade-offs and explain the different rating systems associated with body armor.

While researching this article, I spoke with several different companies to get varied perspectives on this ancient technology, which dates back to the Mycenaean area around 1400 BCE.

Jeremy Gray, former president of HESCO, gave the most concise explanation of body armor I’ve ever heard: “Armor is a mechanical system designed to fail.” It defeats ballistic threats (primarily bullets) by doing one of two things: abrading the projectile or shattering it.

Steel armor essentially shatters the bullet. But as we all (should) have learned in high school physics, a couple things happen as a result. Energy is never created or destroyed; in this scenario, it’s transferred. Some of that energy is the punch you’d feel when the armor takes a hit, but most of that energy makes the round explode on impact, sending spall — tiny lead, copper, or steel fragments — everywhere. “Everywhere” can include your face, head, neck, or other less-than-ideal locations. Secondly, for every reaction there’s an equal but opposite reaction. So, for the energy to be absorbed, it must go somewhere. Hopefully, most of it is transferred into the plate and not your body cavity.

Director of Special Projects at Survival Armor Gary Hughes explained:

“AR500 Steel plates have become popular because of their low cost and their relative thinness and, most of all, likely because of their availability to the mass consumer market. This is the same heat-treated steel that is used in varying thicknesses for steel targets. Your average ¼-inch-thick, AR500 steel rifle plate will pass an NIJ Level III certification, and many manufacturers have chosen to do so.

“As mentioned above, however, that cannot be the only consideration, because steel personal protective inserts have a couple of major downsides.

“In my opinion, the biggest of those is that it has a horrible Achilles’ heel. It will not stop 5.56 M193 55-grain FMJBT [full metal jacket boat tail] ammo out of a 20-inch rifle barrel. Oftentimes, it will stop it out of a carbine, SBR or pistol-length barrel, but a rifle-length-

barrel AR-15 will eat [through] it. We’re talking holes that look like they were professionally put there.”

Above: U.S. Marine Corps Gunnery Sgt. Sean M. Dempsey shows off the hole in the armor plate that saved his life. He was shot in the back by an insurgent in Iraq and walked away with only a bruise. (Photo via U.S. Department of Defense)

Essentially, Hughes commented, some savvy gun guys or Eugene Stoner purists keep 20-inch AR rifles around, and those can easily defeat AR500 plates with your standard 55-grain plinking round. Additionally, and more pointedly, bullets shatter on steel. As a result, many manufacturers coat their plates in aramid — the same compound used to line truck beds — to try and capture the spall. There are certain steel plates, Hughes explained, that are designed specifically to mitigate a M193 cartridge traveling at 3,250 feet per second. However, these are not the run-of-the-mill, low-budget steel plates you’ll find at most retailers. Hughes doesn’t generally recommend steel plates at all, but if you insist on buying some, he says you “should be looking at AR1000 or 647 hardness plates.”

Many traditionalists will claim that steel is the standard, and modern materials like polyethylene (“poly”) plates or ceramic plates are merely fads. However, with innovations in ballistic technology, these plates have their benefits over their steel-clad brethren; they’re lighter, for one, and stop a wider array of threats, especially multiple hits. Of course, many of the diehard steel fans will be the first to point out that with poly or ceramic plates you can’t stack rounds on top of one another.

While this may be true, if you’re standing there letting someone shoot you in the same place repeatedly, something, somewhere, has gone horribly wrong. It’s wise to consider the most likely scenarios under which your armor will be shot in the real world and choose armor accordingly.

Above: These plate carriers from Tyr Tactical demonstrate two variations in armor integration. The minimalist PICO-DS (left, also pictured in this article's lead photo) only carries hard ceramic plates, while the EPIC (center) features ceramic plates plus a layer of soft armor that encircles the torso.

Ceramic and poly plates, by contrast, abrade or shear incoming bullets over a very, very quick period of time.

“The ceramic portion of a ceramic plate shears that bullet, and the armor itself shatters a bit (it’s meant to) and then the backer material captures those fragments so that it doesn’t go through the armor and obviously go into you. It acts like a catcher’s mitt. Those fibers pull apart, and they create a lump on the back of the plate. That’s that ‘backface signature’ that you talk about when you’re talking about NIJ certification where they want a maximum of 44 millimeters backface,” explained Jeremy Gray of HESCO.

But what about poly plates? Surely, they aren’t making a bullet shatter. Correct, they’re shearing and abrading it and doing so very fast with very little weight. “If you have a pure polyethylene plate, you obviously don’t have that strike face to shatter the bullet. It’s a different method, but fibers also actually pull the bullet apart. The polyethylene materials that are used consist of fibers — really long chains of carbon and hydrogen — as well as some sort of resin system that holds those fibers together. When you consolidate those with heat, that’s what is doing the work of defeating the round,” Gray elaborated.

Above: We spoke to Jeremy Gray, former president of HESCO, one of the biggest names in the armor business. HESCO plates have been worn daily by members of the military and law enforcement agencies for more than 20 years.

If you want to geek out on this a bit more, this is called the Van der Waals effect. The materials and chemical processes to make ceramic and poly armor are so strong that they literally pull the bullet apart in milliseconds as it contacts the strike face. Just think about how small a M193 55-grain bullet is, for example, and how fast it moves (up to 3,250 fps). These systems have to do a whole lot of work in an incredibly short period of time. On top of that, many Level III plates are multi-hit rated. That’s nothing short of amazing when you stop and think about it.

“The biggest downside to an all poly, lightweight NIJ-certified Level III rifle plate? A 16-inch AR-15 with M855 ammo will shoot right through it. When people brag to me about their expensive super lightweight Ultra-High-Molecular-Weight Polyethylene (UHMWPE) plates, I generally tell them that’s great, it will make it easier to drag your corpse,” Hughes commented.

“I would wear steel plates before I wore an all-poly plate,” he continued. “The reason for that is simple, I know the American firearms market and community. I know the odds of encountering a 20-inch AR-15 firing M193 ammo is significantly lower than encountering a 16-inch one firing M855. We’re talking about the most popular rifle in the country, and one that’s firing roughly 50 percent of available commercial ammo that would be able to render it useless. We don’t like 50/50 odds in body armor. I wouldn’t wear one, regardless of how nice and light they are. I’d wear steel first … and that’s saying something, because I generally only recommend steel in very narrow circumstances, such as horrific storage conditions, hard use, impacts, drops, etc.,” Hughes continued. This, for context, is why we see the designation Level III+. More on that next.

Above: Armor can be worn covertly or overtly. HighCom offers a Rescue variant of its Trooper ACAP plate carrier that includes high-vis reflective material. It’s designed to be worn by fire/EMS personnel during active shooter and critical incident responses.

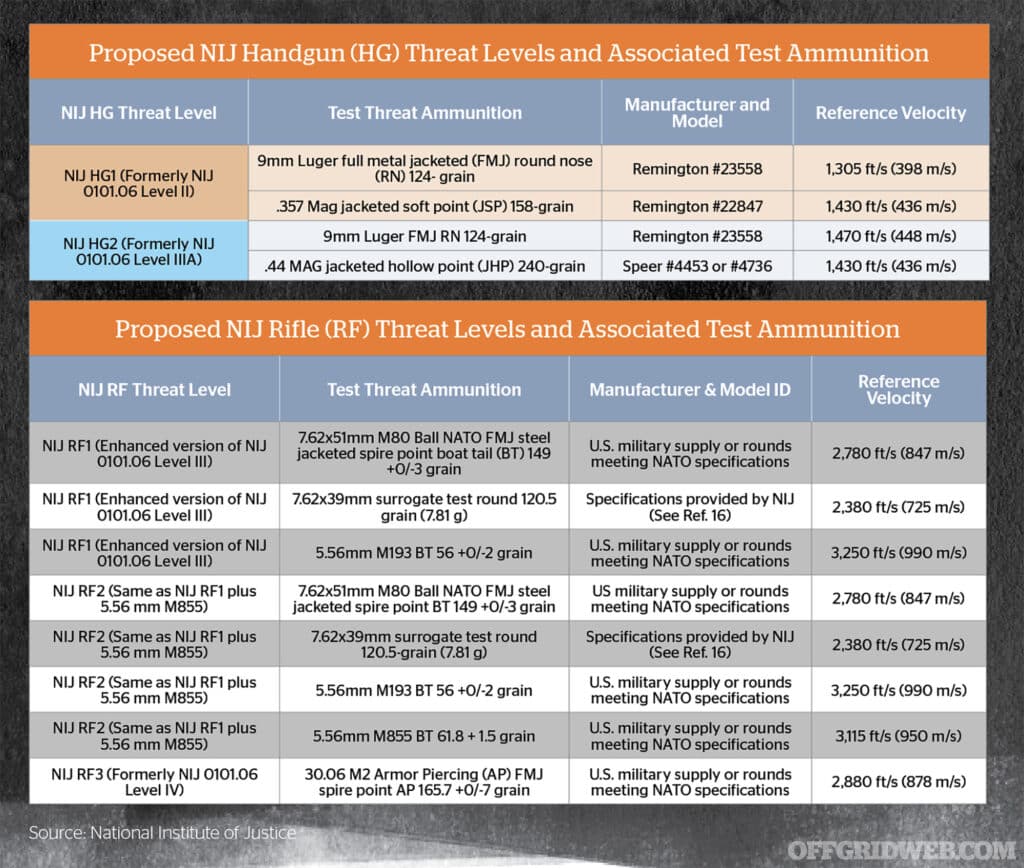

One of the biggest hang-ups and puzzles that surround buying plates are the ratings. There are five NIJ ratings you should be aware of: IIA, II, IIIA, III, and IV. These armor ratings are written as Roman numerals but read as numbers (e.g., 2A). The first three relate to handgun calibers, while the last two apply to rifle calibers.

Let’s be clear on something right out of the gate. There is no “+” designation from the National Institute of Justice (NIJ). They’re the governing body that does most — if not all — of the armor certifications in the U.S. Specifically, body armor has to reach the NIJ 0101.06 standard. However, a new system (0101.07 — got to love the government and their easy-to-remember designations) is allegedly on the way.

“The NIJ Standard 0101.06 is the latest standard published by the National Institute of Justice and sets minimum resistance requirements for soft body armor as well as hard rifle armor. Products that are certified compliant by NIJ can be found on the NIJ CPL list. We explain it a bit more on our NIJ web page and on our blog,” Kelly Gordon, marketing and creative director from HighCom Armor explained.

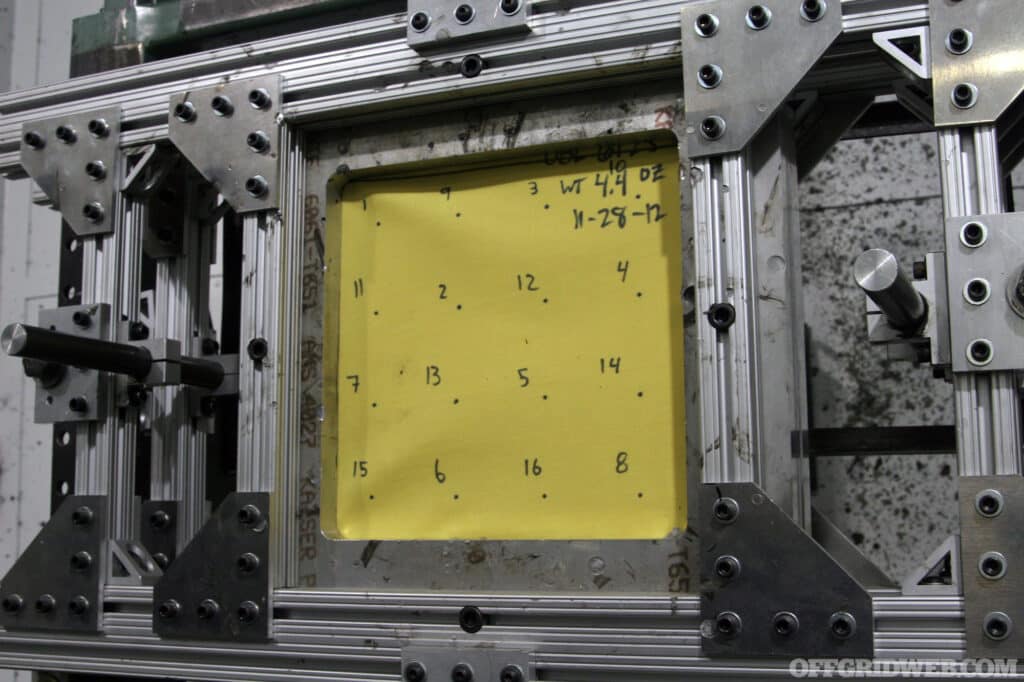

Above: Oregon Ballistic Laboratories (OBL) is a full-service armor testing facility that’s certified by the National Institute of Justice and the U.S. Army Aberdeen Test Center.

“Generally, handguns and assault rifles can fire relatively rapidly, and there is a chance the armor will be hit more than once, so having multi-hit performance with armor is important when the operator comes in contact with those threat levels. Even though our Level IV plate is a single hit for that level of protection, there is still multi-hit protection at lower threat levels,” Gordon explained further. The plus (+) — in the case of HighCom armor and many other manufacturers — indicates that they have performed additional testing above the standard requirements, which we will discuss shortly.

Soft armor ratings, from “weakest” to “strongest,” are arranged as follows: IIA – II – IIIA. One thing we glossed over thus far is handgun rounds, since much of the hard armor has rifle threats in mind. Level IIA soft body armor can stop most standard handgun rounds (9mm, 40 S&W, .38 Special, etc.) with the exception of magnum rounds or perhaps a 9mm from a PCC where it will gain a lot more velocity in a 16-inch barrel than a 4-inch handgun. Level II increases protection to defeat a 9mm doing over 1,100 fps or a .357 Magnum jacketed soft point; IIIA can defeat all of the previous rounds as well as a faster moving 9mm (about 1,400 fps) and a .44 Magnum. In short, IIIA soft body armor can defeat pretty much any handgun round.

Hard armor ratings get a bit more complicated. Level III plates are designed to take multiple hits from a variety of calibers as a rule (all manufacturers differ, so please, please, please look at their tech sheets and understand what they say). For the most part, Level III plates that are NIJ certified can take six hits from the common threat rifle calibers — XM193 (5.56 55-grain ball ammo), M80 (7.62×51 or .308 civilian) and 7.62×39 (common AK rounds, although this gets weird due to quality controls with this type of ammo coming from overseas factories). All the other rounds that are outside of those main rifle threats are why you see the + or ++ designations — they fall out of the NIJ bubble and manufacturers want to denote that their plates may defeat more common calibers that aren’t on the list (for example, .300BLK).

Above: OBL provided these behind-the-scenes photos of one of the ranges where they perform rigorous NIJ armor tests.

Level IV plates can take a single hit from 30-06 M2AP (armor piercing) ammunition. “For Level IV, the only round that NIJ recognizes is 7.62×63 — or 30-06 as it’s commonly known — M2AP. That’s a hardened steel core round traveling at roughly 2,880 fps. The interesting thing for all the velocities for the NIJ is they’re above the muzzle velocity for most of your standard rounds. And when NIJ is talking about velocity, it’s striking velocity, not muzzle velocity,” Gray of HESCO humored me and explained. I learned more from our conversation about muzzle versus striking velocity and ballistics than I did in hours of reading.

“Not all Level III plates will stop green tip but all Level IV plates will. It’s a harder threat to stop and popular. We offer several Level III plates that all stop green tip — 3s14m, 3s9, 3s9m, RSTP, RSTPSA+, RSTPG2. The new NIJ 07 Standard, however, will list green tip as a required threat for Level III plates,” Gordon of HighCom security explained further about their offerings. To be clear, “green tip” is the common term for rounds that are M855 American designation or SS109 everywhere else — mild steel core penetrator rounds. HESCO also calls any of their Level III plates that can defeat a M855 round a Level III+, as you can see on their tech sheets. For example, they also list 7.62×39 HSP (M43) and 7.62x54R — which are commonly fired from AKs and Mosin Nagants respectively — as capable of being defeated by Level III+ plates, but these again are not within the NIJ 06 certification bubble.

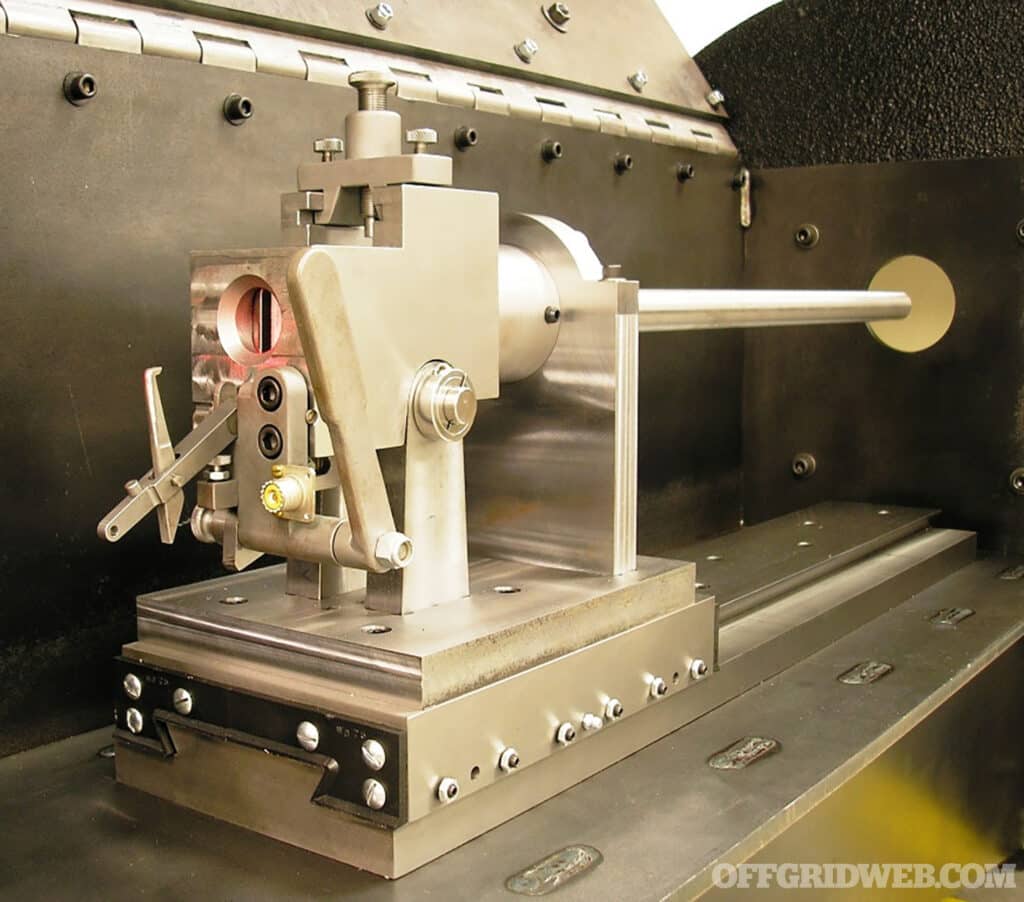

Above: OBL testing equipment.

There are also products that are DEA or Rifle Special Threats rated. These don’t fit within the guardrails of the NIJ 06 rating, and thus can’t be certified as such, but that doesn’t necessarily mean they can’t stop rounds or are otherwise unsafe. The DEA, in fact, has some pretty high round-stopping standards, and you can see some of this on HESCO’s tech sheets.

The biggest takeaway when it comes to ratings is the following: figure out what you’re trying to stop, your likely use case, your probable threats, weight, and budget. If you’re wearing armor all day or using it in a professional setting, you need to give careful consideration to how much weight versus protection you want, but you probably want to stop rifle rounds and quite a few of them. Personally, I’d opt to have a little more weight and be better protected, but that’s just me. If you’re a civilian and will likely only need to throw your plates on in a SHTF situation, that’s a different story. In that case, you may be using armor more to defend a static position (e.g. your home) and it may be wiser to go with the most protection you can afford while considering weight a lower priority. It’s all about trade-offs.

Above: OBL testing equipment.

NIJ certification testing, as you can imagine, is a robust, brutal, and very specific series of tests that armor must pass to earn the NIJ seal. The new standard, NIJ 07, has been promised since 2016, but right now they’re abiding by the NIJ 06 standard.

“The process to get a plate certified is quite lengthy. Last time we got a plate certified it took about four months,” Gray of HESCO said. “There are a lot of things the NIJ does. As a manufacturer, you have to submit nine plates for a Level III certification — eight for testing and an extra. The new standard [0101.07] will increase the number of plates for RF1 and RF2 significantly. The original draft called for 27 plates for testing (nine for each threat), but the rumblings about the revision to the draft is that there will be twice that number because NIJ now wants to test obliquity. So, that’s 54 plates, which is a lot. The Level IV or RF3 will call for 37 plates for V0 and V50 and another 37 for obliquity,” he continued.

Those plates will go into a conditioning chamber for 11 days and are subjected to various temperatures, humidity, and the like. Then comes the drop test.

The plate is attached to a 4-foot-tall arm with a weighted back, and each plate is then slammed down twice. And don’t forget, that’s after 11 days of being subjected to all of the differences in temperature and humidity.

If a plate survives to this point, then and only then does it get shot. For a Level III, it needs to get shot six times. After it takes rounds, they perform what’s called a V0 test — basically, is there a penetration or not? Four plates go through this process.

Above: It’s wise to consider the calibers and weapon configurations you might be up against. Understanding armor ratings — including the unofficial “+” designations — can help you determine what you truly need.

Then, there’s a V50 test. This test is wild in that they increase the velocity of the threat projectile until you get 50 percent of the rounds passing through the plates. Sometimes to achieve this V50 failure velocity, the case is maxed out to the point that no more powder can be crammed in, or the barrel/weapon system simply can’t take it. This is more theoretical, as opposed to being something that would ever happen in real life. It’s simply establishing what the safety factor is for that plate. Another four plates go through this process.

“The NIJ wants a calculated failure rate of below 5 percent for a given plate. Most of our [HESCO] plates are less than 0.1 percent failure rate,” Gray mentioned in a matter-of-fact manner. That’s 50x better than the NIJ standard. You can double check my math.

From a laboratory perspective, you need to reproduce reliable results every single time with these plates. The NIJ takes it seriously, and rightfully so — there are lives on the line. If a manufacturer is ISO certified, they tell the NIJ they can test their plates every 24 months, off the line, at the manufacturer's expense, to ensure their quality controls are up to par. If not ISO certified, this happens every 12 months. For even more context, they send the plates out to one of a handful of companies to inspect and test them, and the manufacturer can go and watch the tests to be a witness.

Above: Body armor has many applications for numerous vocations (Photo by Joey Skibel).

This is the difference between NIJ certified and NIJ compliant. Clearly, certification is far more rigorous, costly, and time-consuming.

When we talk about the standard a Level IV plate needs to pass — defeating a 30-caliber M2AP round — we’re really talking about a .30-06 round with a hardened steel core that was made in the 1950s. There aren’t many of them floating around. Even for testing in the factory, many of these rounds were pulled from old ammunition stockpiles. Each round is loaded individually, they measure the amount of powder that is poured into it, etc. There are strict lab standards, and furthermore, in testing they upcharge these rounds to obtain a striking velocity of 2,880 fps — roughly 5 percent faster than a standard round would produce at the muzzle. Said another way, they’re testing in a worst-case scenario type of way. But for this reason, Level IV plates are only tested to be hit one time by M2AP rounds. That might not sound like a great stat, but a standard M2AP round is capable of penetrating half an inch of steel from nearly 100 yards.

The tests are absolutely brutal before they’re even shot, and then during.

The new NIJ 0101.07 standard will be much easier to navigate than current armor ratings, as it’s supposed to break down what armor can defeat a threat level from HG (handgun) 1-3, with 3 being the most robust, and the same for rifle. The chart below outlines the new designations, test threat ammo and reference velocities for NIJ 07. Once more, this rating system hasn’t officially been put in place yet.

Like pretty much everything, there’s no easy button. You need to think about your use, how much weight you want to carry, and what you want to stop. While budget is and should be a concern, you must ask yourself: how much is your life, or your loved one’s life worth? Would you really want to go to all the trouble of buying and wearing armor, only to end up laying on the ground with holes in you wishing you sprang for better plates with high-velocity hit capabilities?

As I mentioned at the outset, the purchasing decision is all about you and your personal use, but also about trade-offs. Steel is cheaper and has multi-hit capabilities, but is heavy, there’s a spall factor, and if not finished right, the steel becomes brittle. Also, as many of the industry experts in this article have pointed out, 20-inch barrels shooting XM193 can bore through some of the steel plates easily. With poly plates, of course, they’re lighter, but historically don’t handle multiple hits from green tip unless you go the more expensive route.

Ceramic is a great do-all plate. Across the industry with all of the professionals I spoke to for this article, it seems to be the best way to balance performance and weight while having an eye toward cost. Everyone thinks of ceramic and thinks of dinner plates that crack if they’re set down on the counter too hard — they’re nowhere near that fragile. Not even close. You could hit many of them full-force with a sledgehammer, and they would still be operational. There are some formulas that are more brittle than others, but all of them will stand up to normal wear and tear just fine. You mostly need to be cautious if you work in a high-tempo, high-speed operational environment like a QRF or military unit, as ceramic can break or become brittle with years of heavy use. Many plates are marked with a 5- to 10-year shelf life, but that’s more for liability purposes than anything — your plates can last a lot longer if they’re stored appropriately and not abused.

Subscribe to Recoil Offgrid's free newsletter for more content like this.

Editor's Note: This article has been modified from its original print version for the web.

STAY SAFE: Download a Free copy of the OFFGRID Outbreak Issue

STAY SAFE: Download a Free copy of the OFFGRID Outbreak Issue

No Comments